Creative Company, Reliable Company, Leading Company, Yeongnam Bolt

Product

| Diameter | Pitch | d1 | H | B | C | S | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Coarse | Fine | Basic | Tolerance | Basic | Tolerance | Basic | Tolerance | App. | App. | |

| M12 | 1.75 | 1.25 | 12 | 0 -0.25 |

8 | ±0.3 | 19 | 0 -0.8 |

21.9 | 30 |

| (M14) | 2 | 1.5 | 14 | 9 | 22 | 25.4 | 34 | |||

| M16 | 2 | 16 | 10 | 24 | 27.7 | 38 | ||||

| (M18) | 2.5 | 1.5 | 18 | 12 | ±0.35 | 27 | 31.2 | 42 | ||

| M20 | 2.5 | 1.5 | 20 | 0 -0.35 |

13 | 30 | 34.6 | 46 | ||

| (M22) | 2.5 | 1.5 | 22 | 14 | 32 | 0 -1 |

37 | 50 | ||

| M24 | 3 | 2 | 24 | 15 | 36 | 41.6 | 54 | |||

| (M27) | 3 | 2 | 27 | 17 | 41 | 47.3 | 60 | |||

| M30 | 3.5 | 2 | 30 | 19 | ±0.4 | 46 | 53.1 | 66 | ||

| (M33) | 3.5 | 2 | 33 | 0 -0.4 |

21 | 50 | 57.7 | 72 | ||

| M36 | 4 | 2 | 36 | 23 | 55 | 0 -1.2 |

63.5 | 78 | ||

| (M39) | 4 | 2 | 39 | 25 | 60 | 69.3 | 84 | |||

| M42 | 4.5 | - | 42 | 26 | 65 | 75 | 90 | |||

| (M45) | 4.5 | - | 45 | 28 | 70 | 80.8 | 96 | |||

| M48 | 5 | - | 48 | 30 | 75 | 86.5 | 102 | |||

| (M52) | 5 | - | 52 | 0 -0.45 |

33 | ±0.5 | 80 | 92.4 | 110 | |

| M56 | 5.5 | - | 56 | 35 | 85 | 0 -1.4 |

98.1 | 118 | ||

| (M60) | 5.5 | - | 60 | 38 | 90 | 104 | 126 | |||

| M64 | 6 | - | 64 | 40 | 95 | 110 | 134 | |||

| Nom sized | Outsidedia. external. thread |

B | C | d2 | X | V | S | a-b | E | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dimensional Standards | Tolerance | approx | Dimensional Standards | Tolerance | approx | approx | Dimensional Standards | Level | Tolerance | Max | ||

| M16 | 16 | 16 | ±0.3 ±0.20 -0.10 |

13.1 | 13.6 | 0 -0.5 |

2 | 3 | 30 | +5 0 |

0.8 | 1' |

| 20 | 20 | 20 | 16.4 | 17.1 | 2 | 3 | 35 | +6 0 |

0.9 | |||

| 22 | 22 | 22 | 17.8 | 18.9 | 3 | 4 | 40 | 1.1 | ||||

| 24 | 24 | 24 | 19.5 | 20.3 | 4 | 4.5 | 45 | 1.2 | ||||

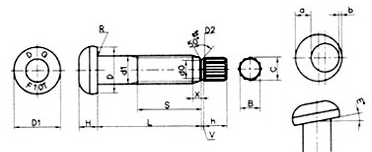

| Nom sized | Outsidedia. external. thread |

d1 | D | D1 | H | R | a-b | E | h | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dimensional Standards | Tolerance | Dimensional Standards | Tolerance | approx | Dimensional Standards | Tolerance | approx | Level | Tolerance | approx | ||

| M16 | 16 | 16 | +0.7 -0.2 +0.8 -0.4 |

27 | ±0.1 | 26 | 10 | ±0.8 | 1.6 | 11.40 | +0.10 | 15 |

| 20 | 20 | 20 | 34 | 33 | 13 | ±0.9 | 14.20 | 18 | ||||

| 22 | 22 | 22 | 38.5 | 37 | 14 | 15.70 | 19 | |||||

| 24 | 24 | 24 | 43 | 31 | 15 | 2.0 | 17.30 | 20 | ||||

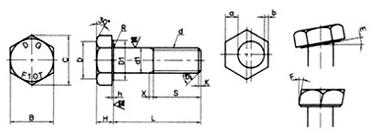

| Nom sized | Outsidedia. external. thread |

H | B | C | D | D | a-b | E | F | h | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dimensional Standards | Tolerance | Dimensional Standards | Tolerance | approx | approx | Min | Max | Max | Max | approx | ||

| M12 | 12 | 12 | ±0.35 | 22 | 0 -0.8 |

25.4 | 20 | 20 | 0.5 | 1 | 2 | 0.6 |

| 16 | 16 | 16 | 27 | 31.2 | 25 | 25 | 0.8 | |||||

| 20 | 20 | 20 | ±0.4 | 32 | 0 -1 |

37 | 30 | 30 | 0.9 | |||

| 22 | 22 | 22 | 36 | 41.6 | 34 | 34 | 1.1 | |||||

| 24 | 24 | 24 | 41 | 47.3 | 39 | 39 | 1.2 | |||||

| Nom sized | d1 | H | B | C | D | D1 | r | K | a-b | E | F | h | S | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dimensional Standards | Tolerance | Dimensional Standards | Tolerance | Dimensional Standards | Tolerance | approx | approx | Min | Radius | approx | Max | Max | Max | approx | Dimensional Standards | Tolerance | |

| M12 | 12 | +0.7 +0.2 |

8 | ±0.8 | 22 | 0 -0.8 |

25.4 | 20 | 20 | 0.8 ~ 1.6 | 2 | 0.7 | 1 | 2 | 0.6 | 25 | +5 0 |

| 16 | 16 | 10 | 27 | 31.2 | 25 | 25 | 1.2 ~ 2.0 | 0.8 | 30 | ||||||||

| 20 | 20 | +0.8 -0.4 |

13 | ±0.9 | 32 | 0 -1 |

37 | 30 | 29 | 2.5 | 0.9 | 35 | +6 0 |

||||

| 22 | 22 | 14 | 36 | 41.6 | 34 | 34 | 1.1 | 40 | |||||||||

| 24 | 24 | 15 | 41 | 47.3 | 39 | 39 | 1.6 ~ 2.4 | 3 | 1.2 | 45 | |||||||

| Category | T/S BOLT | H/T BOLT |

|---|---|---|

| Set Setup | 1 set: One bolt, nut, washer | 1 set: Two bolts, nuts, washers |

| Fastening Tool | Its very own electronic wrench tool is light-weight and easy to operate (Electronic tools). | Air Impact tools can be heavy and increase fatigue of the operator. Increased inconvenience because of moving between layers of the air compressor and air hoses. Nut runner tools are expensive. |

| Torque Consistency | As the bolt’s notch is cut at a constant torque, one can confirm torque connection. Perfect installation, as sufficient clamping force is guaranteed through consistent torque. |

Not possible to conduct work using consistent torque; consistent torque cannot be guaranteed because worker must use his discretion. When connecting the nut, the bolt might rotate together. |

| Preventing Noise | Installation in urban areas can be done without noise, minimizing damage caused to the surroundings. Prevents hearing loss of the operator. |

Noise of impact tools is severe, creating noise pollution when installing in urban areas. Construction might be suspended due to people petitioning. |

| Reduced Construction Duration | BShortened fastening time, due to no more idle rotation when fastening the bolt. When installing steel structures, construction duration is significantly shortened as fastening time is reduced by half the time it takes when using standard H/T bolts. |

Delayed fastening due to idle rotation requiring primary assembly before tightening. |

| Tightening Inspection | Tightening inspection using a torque wrench is not required. Tightening using pre-set torque can be visually inspected. |

Requires tightening inspection using a torque wrench. Cannot inspect tightening visually. |